Saving cash while keeping the balance in the Supply Chain Triangle of Service, cost and cash is difficult. Many companies nowadays are under pressure to lower the inventories without having an impact on the service or cost side. So how can multi-echelon inventory optimization help organisations to achieve that goal?

From a financial perspective, the organization’s ROCE (Return on Capital Employment) is an important metric. This financial ratio, which measures a company’s profitability and the efficiency with which its capital is employed, expresses the value received for money spent – or in other words the ‘bang for your buck’. I firmly believe that applying multi-echelon inventory planning will seriously leverage the ROCE. The ROCE is calculated as follows: EBIDT ÷ capital employed. Since the capital employed consists of your fixed assets and your working capital, reducing the inventory throughout the whole supply chain will have a significant impact. I would even go so far as to say that tackling the inventory in each step of the supply chain and across company boundaries could reduce an organization’s inventory by 50%.So, why are companies not massively investing in multi-echelon inventory optimization? Well, there are three reasons: trust, trust and trust. To collaborate with suppliers and customers, all parties must be prepared to sit around the table in openness and to align their processes together. In my view, smooth cooperation comes down to better planning. Up till now, unfortunately, I have never attended an S&OP meeting to which suppliers and customers have been freely invited.

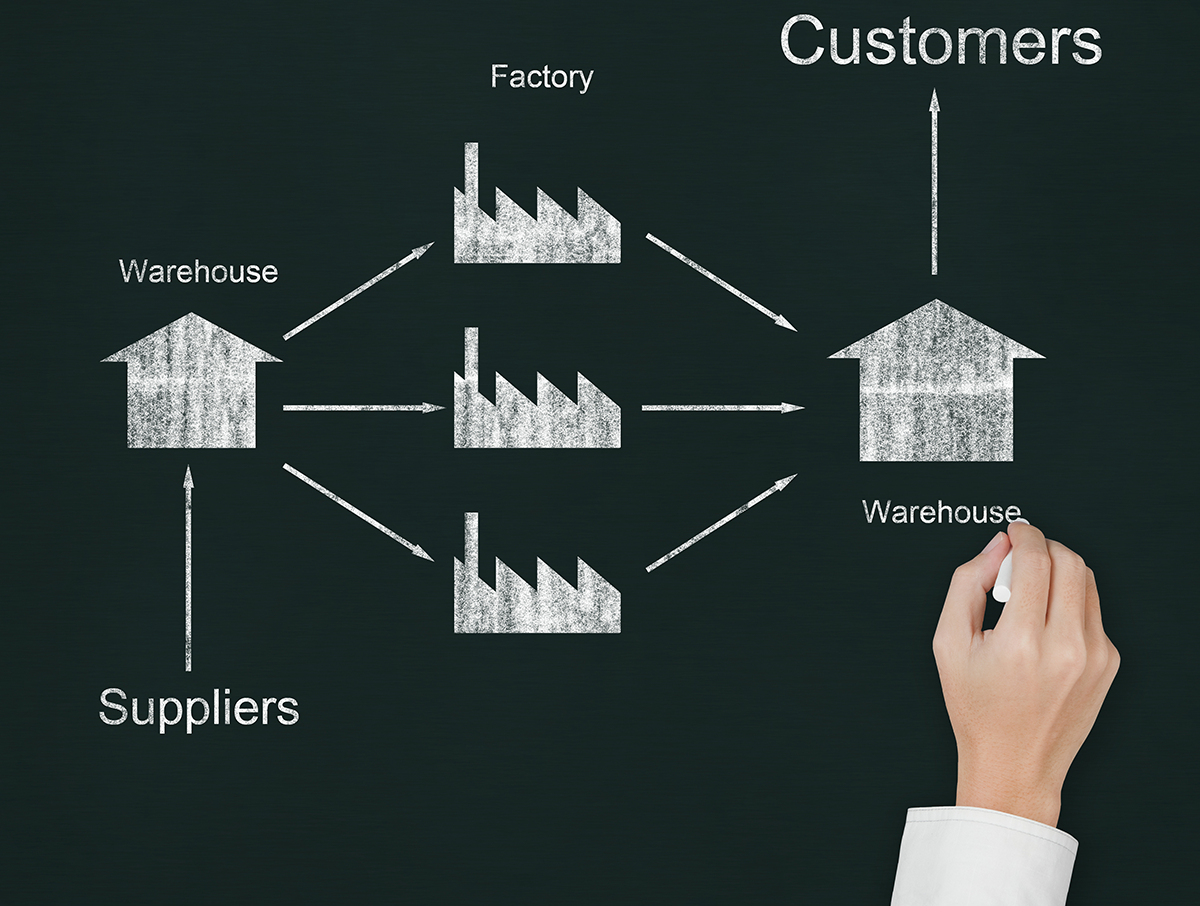

Unlike today’s standard practice, in which the inventory parameters are typically calculated separately for each step in the value chain, a multi-echelon inventory tool creates them for the chain as a whole. Computing throughout the chain allows you to make a strong business case for closer collaboration.

Multi-echelon inventory optimization will not only lower the inventory costs and thus increase the working capital, but it also will lead to cost reductions in other areas. If there is complete openness, suppliers will be able to deliver their products at the most optimal moment for the customer. Instead of putting all the goods in the racks, the organization could then decide to install a mega cross-dock operation and ship the goods directly to the distribution points. Although multi-echelon inventory optimization only takes the stock into account, it also has the power to significantly improve other processes and hence the entire organization.

So, imagine what you could do with 50% of your working capital in cash. Would you use it to improve your customer service, to create a broader product portfolio or to lower your prices and gain more market share?

Interested to read more about inventory optimization?

These Stories on Inventory Planning