.png)

Supply chains come in all shapes, sizes, and complexities. And supply chain management needs to adapt and plan ahead to keep everything flowing smoothly. That is why we will discuss how you can get the most out of your unique supply chain in this blog series. To guide us through this series we start each of our topics with a meaningful film quote that explains the core of our story.

The quote that inspired me for this topic:

“You give 'em one message: I want Sollozzo. If not, it's all-out war: we go to the mattresses.”

Some of you might be unfamiliar with this quote from The Godfather, which means as much as ‘preparing for battle’. But what does this warlike language has to do with supply chains? Read further and I will connect these dots for you.

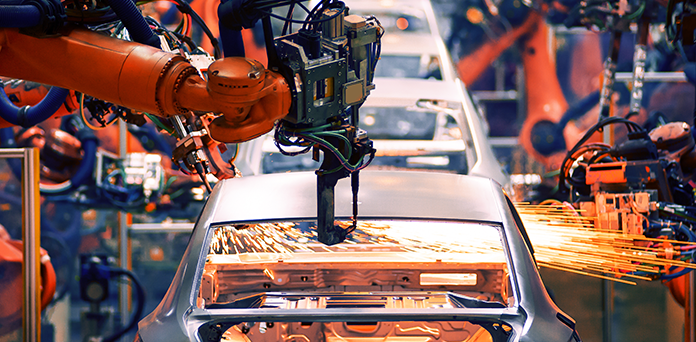

You don’t have to look far to see the resemblances between actual battles and those that take place in the supply chain world. Let’s take the car manufacturing industry for instance. Car companies are currently in multiple supply chain battles for resources (such as computer chips or battery parts), production capacity (due to missing resources) and transport (due to shortages of drivers, tracks and shipping containers). Add to this volatile combo the ongoing war for talent and the continuous struggle to convince customers to buy your brand and you get a total war that spans the entire supply chain.

Whenever external, political and macro-economic circumstance are unstable, it’s crucial you can predict with some certainty what the effects will be on your own supply chain. That’s how you can protect your own supply chain and preserve your resource streams and production capacity. Wars of the past have been won and lost due to strong or weak logistics. So it makes sense that an actual supply chain should follow the same rules. If you’re able to keep your supply streams intact under challenging circumstances, or keep them flexible, you’re set to come out the other end in good, if not better, shape.

A lot of what I’ve touched upon until now has, of course, shifted up a gear due to the recent conflict in Ukraine. In a way, reality has caught up with fiction and its implications on trade markets around the world cannot be underestimated. Oil, gas, grain, and multiple other crucial resources are in short supply, and when the demand for something vastly outnumbers its availability, you get even more strife between competitors inside our outside their own sectors.

It also means that you as a company need to (re)negotiate with your suppliers more often if you want to keep the relationship you have with them going. Mutual trust and reliability play a big factor in this. If you don’t have a great relationship with your suppliers, competitors can swoop in with better deals and quickly leave you without any resources coming in. In order to avoid losing suppliers, you need to be transparent and trustworthy towards them about your production plans for the long haul. By creating strong connections with them, you’ll be able to secure those long-term commitments you’re ultimately looking for in a healthy supply chain.

"By creating strong connections with them, you'll be able to secure those long-term commitments you're ultimately looking for in a healthy supply chain."

This continuous game of long-term forecasting lets you anticipate the battle for raw materials and semi-finished products better, which is no unnecessary luxury in the current economic circumstances. Suppliers might be jacking up the prices for difficult-to-acquire resources, but they are still looking for long-lasting partnerships with their customers, even when everything returns back to normal. Even the hostile mafia families in New York City had to get back around the table after significant losses on all fronts. And that’s exactly the reason why you should keep your suppliers close, because we’re all in this together.

Anticipate future supply chain struggles with the necessary ammunition to predict what will likely happen in your market in the coming months. Detect in advance which external, macro-economic forces will influence your supply chain and sales. By creating a digital twin of your company, it is possible to go through all kinds of scenarios without any danger to its real sibling. In turn, these predictive data will help you to make better long-term business decisions and achieve your sales targets.

Even Don Vito Corleone was almost assassinated through excellent forecasting. The titular character of The Godfather goes to buy oranges from a fruit stand. Because Sollozzo's hitmen knew where he would be and when he would be there, they were able to ambush him without much resistance. Luckily for the Don, he survived this particular attempt on his life, but a lot of companies haven’t been so lucky in recent years as they had to change their supply chain strategies almost at a moment’s notice. Are you prepared for the upcoming battles? Get your ammunition ready and powered up so you don't follow into the footsteps of your unfortunate predecessors!

Download our whitepaper to discover how to turn your S&OP process into a true scenario-based decision-making process. To improve your supply chain triangle and to steer your organization towards success, a mature Executive Sales and Operations Planning (S&OP) process is key!

The following articles may also be of interest to you:

These Stories on S&OP